Material Handling Carts

Maximizing Efficiency in Computer Component Manufacturing

Material handling carts play an integral role in computer component manufacturing facilities and enable the movement of delicate and often tiny computer parts from one station to the next. Well-designed material handling carts contribute significantly to the overall efficiency and productivity of these facilities while being designed ergonomically for operator comfort and safety.

The Role of Material Handling Carts

In a manufacturing setting, particularly for computer components, material handling carts are used to transport equipment, various components and materials safely.

They are essential in transporting raw materials to the assembly line, moving partially assembled components from one workstation to another, and in the final transportation of assembled products to the packaging department or the warehouse.

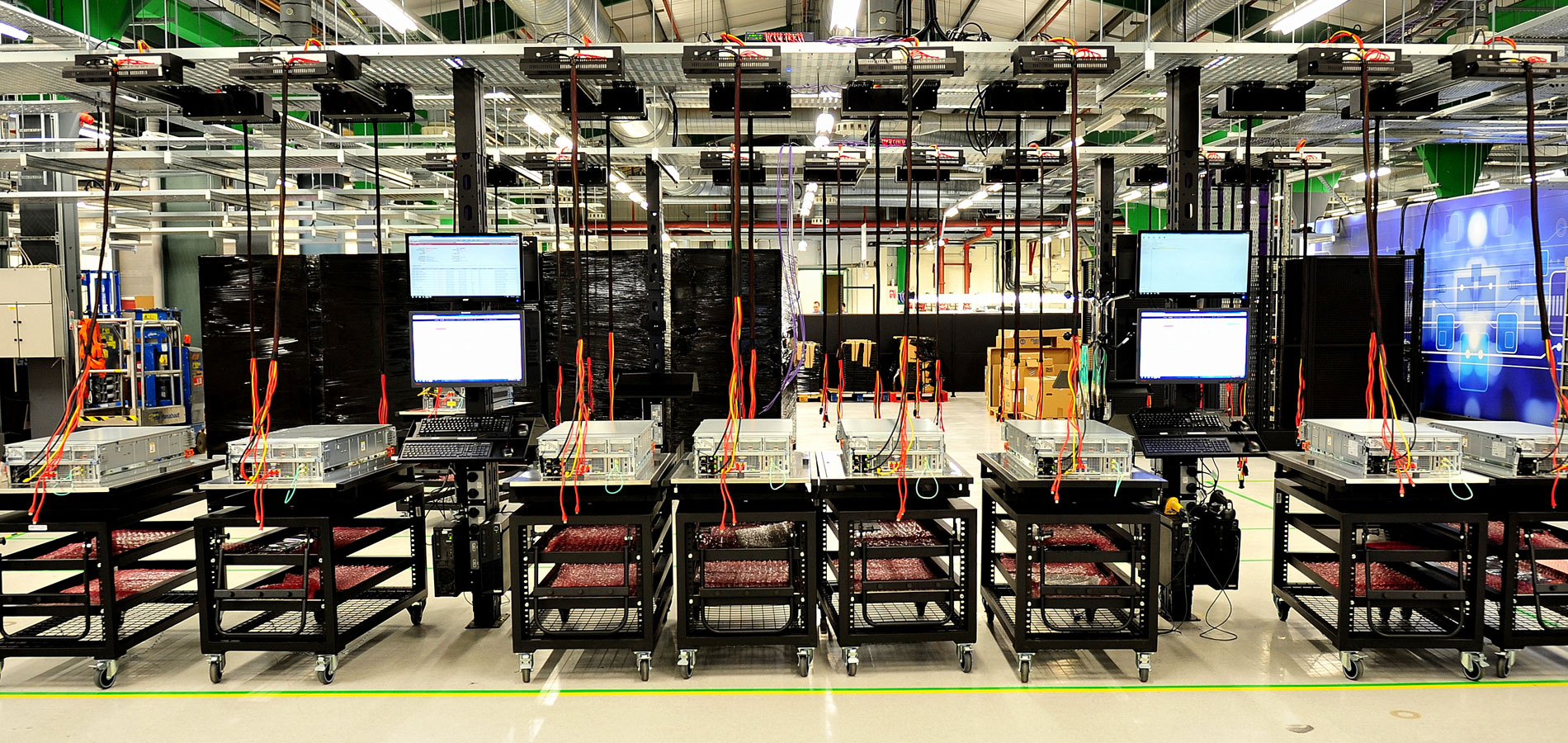

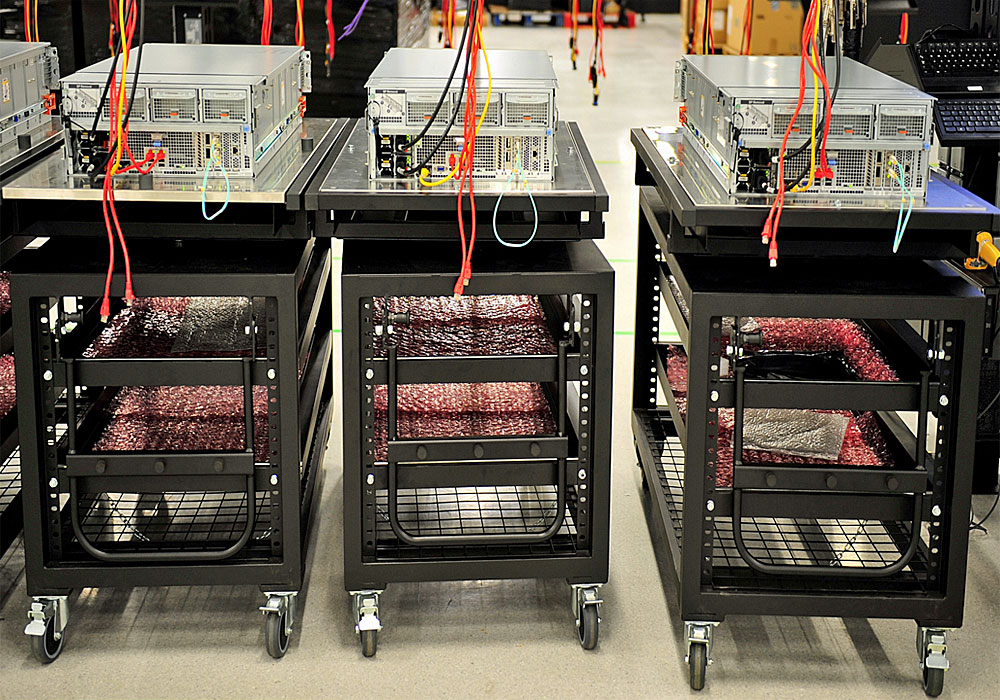

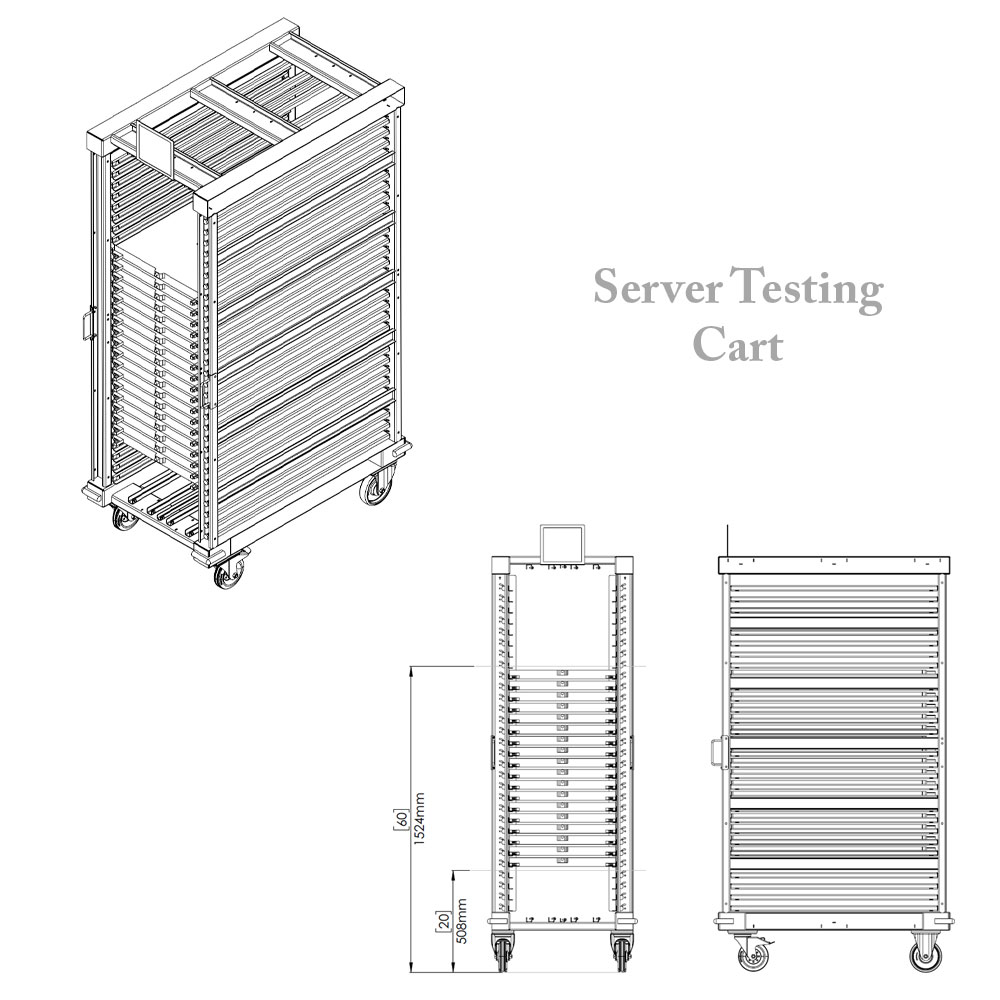

The carts can be used to transport assembled ICT equipment to a test environment for direct plug-and-test testing. NGS also provide cable pillars for server and disk testing and for server warehouses

Features of Good Material Handling Cart Designs

- Ergonomics: Well-designed carts prioritize user comfort and ease of use. The height of the cart, placement of handles, and other design aspects should minimize strain on workers. The CDC recommends that you “talk to equipment vendors” and “consult with an expert in ergonomics to provide insights into improvements…and potential value” in making workplace material handling equipment more comfortable to use for the workforce.

- Load Capacity: The cart must be designed to hold the maximum weight of materials that it will need to transport, providing safety and durability.

- Mobility: Carts should be easy to maneuver, with high-quality wheels and casters that can handle the weight load and the facility’s floor type while dissipating any static electricity generated.

- Durability: The materials used in the cart’s construction should be robust and resistant to wear and tear, ensuring the cart can endure a busy manufacturing environment.

- Safety Features: Brakes, guard rails, and even color-coded sections can enhance the safety of the cart’s use, reducing the chances of accidents.

- Modularity: A versatile cart can adapt to changing needs. Adjustable shelving or removable sides offer flexibility in usage.

- Integration with Other Systems: The cart design should be compatible with other systems in the facility, such as conveyor belts or automated machines, ensuring seamless operations.

How Material Handling Carts Improve Efficiency

Material handling carts streamline operations, saving time and reducing manual labor and facilitate the easy and safe transportation of materials, minimizing potential damage and increasing productivity. Efficient material transportation reduces idle time between workstations, keeping the production process flowing with on-time delivery.

Workers who use ergonomically designed carts experience less physical strain, reducing the risk of injuries and improving overall job satisfaction, directly translating to better productivity.

Material handling carts are much more than simple transportation tools in the computer component manufacturing industry – they are fundamental elements that contribute to operational efficiency, worker safety, and productivity. Manufacturers can ensure they provide the best material handling carts that best serve their unique needs by selecting an engineering firm has experience in their field and can design, produce and deliver their project with the highest standards.

NGS Engineering has the capability to design and manufacture custom material handing carts with castor wheels and customized ESD (electrostatic discharge) paints to protect sensitive electronics in the manufacturing and assembly processes. We are engineering experts in the field of IT product manufacturing including consumer technology like pcs, laptops, servers, data centers, etc. Our designs are configured to prioritize the safety and efficiency of the operator throughout the manufacturing process.

NGS has the experts to provide the design assessment for custom fabrications and advise on safety and efficiency integrations with other systems such as conveyors, assembly stations, pack out stations, etc.

Request a consultation for your custom material handling trays, carts or trolleys with one of our experts today…